Description

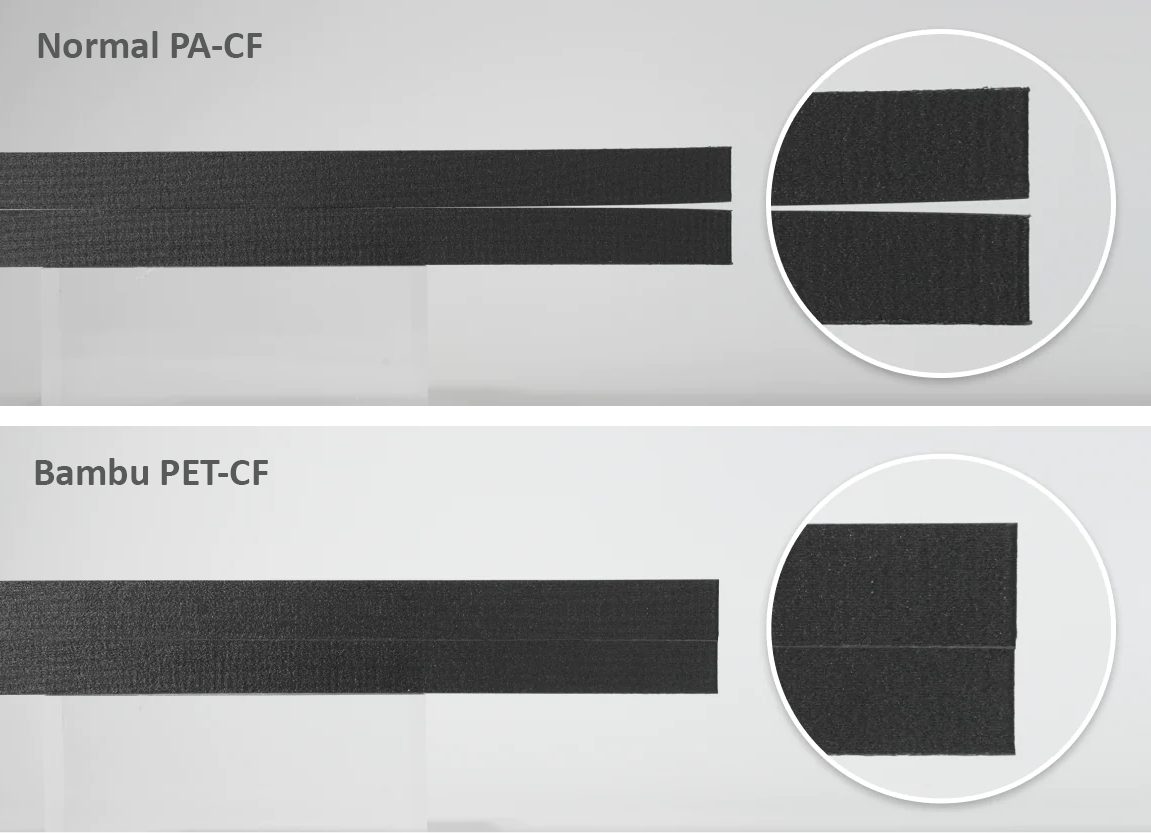

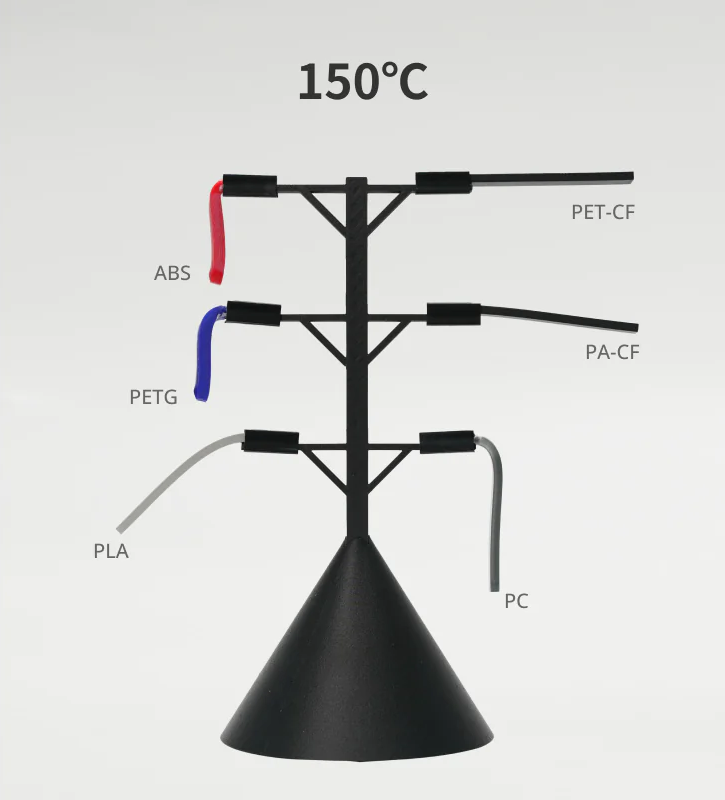

Bambu PET-CF is a blend of tough PET and carbon fiber. Carbon fiber improves hardness and mechanical strength, while still help maintain the low warping and shrinkage of ordinary PET. Bambu PET-CF has excellent high temperature resistance and a soft glow appearance. Its excellent strength, heat resistance, dimensional stability and low moisture absorption make Bambu PET-CF an ideal choice for load-bearing structures or prints used in high temperature and humid environments.

Printing Tips

- While printing, it is more recommended to use an enclosed printer, as layer bonding of some prints may become compromised due to overcooling.

- Drying conditions: 80℃ for 8 hrs. PET-CF is highly sensitive to humidity. To achieve optimal printing performance, it is recommeded further drying before use and after storage. For more details please refer to: Filament drying instructions on Bambu Lab Wiki.

- To prevent the material from absorbing moisture, it is recommended to use an airtight storage container with desiccant during printing. For more details, please refer to:Printing tips for Engineering materials on Bambu Lab Wiki.

- Bambu PAHT-CF comes with a high-temperature resistant spool, which is not prone to deformation in the drying process. Continuing our concept of reducing plastic waste, the spool can also be reused with other Bambu refills.

- Bambu PET-CF isn't compatible with AMS

Model Overview

| PET-CF | PAHT-CF | |

|---|---|---|

| Composition | PET, carbon fiber | PA 12 and other long-chain PA, carbon fiber |

| Hotend Compatibility | Hardened Steel 0.6 (recommended), 0.4, 0.8 mm | |

| Build Plate Compatibility | Engineering Plate, High Temperature Plate, Textured PEI Plate | |

| Glue | Glue Stick / Liquid Glue | Glue Stick |

| AMS Compatibility | No | Yes |

| Print Speed | <100 mm/s | |

| Toughness (Impact Strength - XY) | 36.0 kJ/m² | 57.5 kJ/m² |

| Strength (Bending Strength - XY) | 131 MPa | 125 MPa |

| Stiffness (Bending Modulus - XY) | 5320 MPa | 4230 MPa |

| Layer Adhesion (Impact Strength - Z) | 4.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistant (HDT, 0.45 MPa) | 205 ℃ | 194 ℃ |

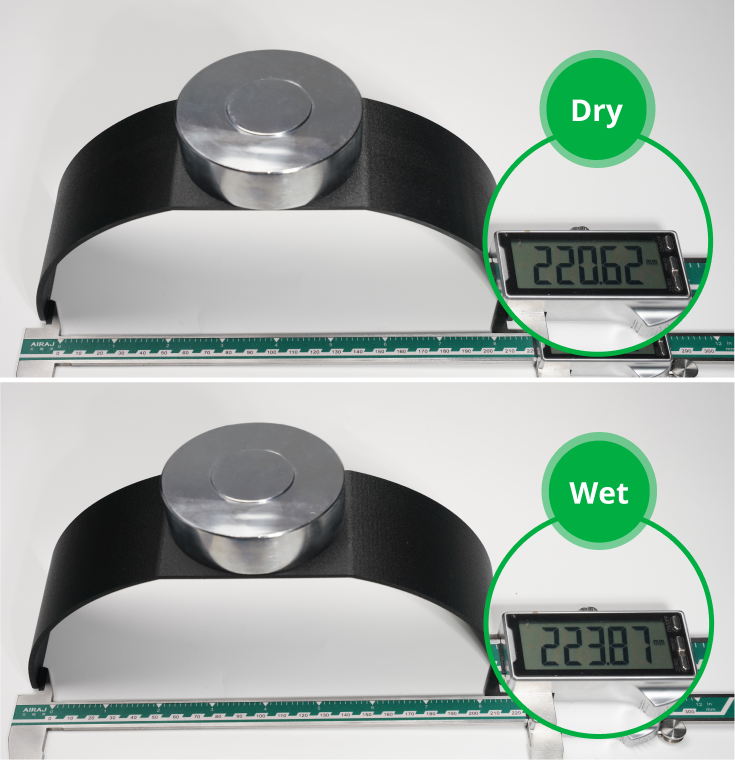

| Saturated Water Absorption Rate / % (25 ℃, 55% RH) | 0.37 | 0.88 |

| Recommended Printing Settings | |

|---|---|

| Drying Settings (Blast Drying Oven) | 80 ℃, 8 - 12 h |

| Printing and Keeping, Container's Humidity | <20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 260 - 290 ℃ |

| Bed Temperature (with Glue) | 80 - 100 ℃ |

| Printing Speed | < 100 mm/s |

| Physical Properties | |

| Density | 1.29 g/cm³ |

| Vicat Softening Temperature | 226 ℃ |

| Heat Deflection Temperature | 205 ℃ |

| Melting Temperature | 250 ℃ |

| Melt Index | 25.3 ± 2.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 74 ± 6 MPa |

| Breaking Elongation Rate | 4.5 ± 1.2 % |

| Bending Modulus | 5320 ± 270 MPa |

| Bending Strength | 131 ± 6 MPa |

| Impact Strength | 36.0 ± 2.7 kJ/m² |

Package Contents

- Filament x 1 & Desiccant x 1

- Package x 1

- Filament Label x 1

Features

FAQs

Q:

What is the difference between PET-CF and PETG-CF?

A:

The primary difference between PET-CF and PETG-CF lies in their base material. PETG-CF is a reinforced material made by adding carbon fiber to glycol-modified polyethylene terephthalate (PETG), while PET-CF is to polyethylene terephthalate (PET). The key difference 'G' in PETG stands for glycol. PETG is a glycol-modified version of PET that contains small amounts of glycol as a co-monomer. The addition of glycol to PETG reduces its crystallinity and makes it more transparent. However, it also reduces its strength and stiffness.

Q:

The difference in application between PETG-CF and PET-CF?

A:

PETG-CF is a versatile basic material that is suitable for printing everyday items, such as bent, folded, and movable parts, due to its excellent toughness and ease of printing. PET-CF, in contrast, contains a greater amount of carbon fiber and is significantly stronger and more temperature resistant compared to PETG-CF. PET-CF is a professional-grade engineering material that is suitable for use in more complex and demanding environments.

Q:

What is PET-CF used for?

A:

Due to its dimensional stability and lower water absorption rate, PET-CF is a better choice than nylon for printing functional parts used in high humidity environments. Also, its high-temperature resistance and low warping make it suitable for printing mechanical assembly parts, such as automotive accessories and fixtures.

| Shipping weight: | 0.90 Kg |